Air Pollution Control Systems — Industrial Dust, Fume & Mist Filtration

Industrial processes generate airborne dust, fumes, and oil mist that reduce product quality, harm equipment, and pose serious safety risks for operators. AirProControl delivers engineered Air Pollution Control systems designed for continuous, reliable, and energy-efficient operation across pharmaceutical production, manufacturing, chemical processing, food facilities, textile plants, mining sites, and wood industries. From critical clean environments to heavy-dust applications, our solutions ensure safe, compliant, and stable air quality under all operating conditions.

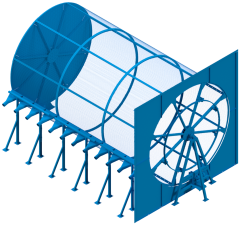

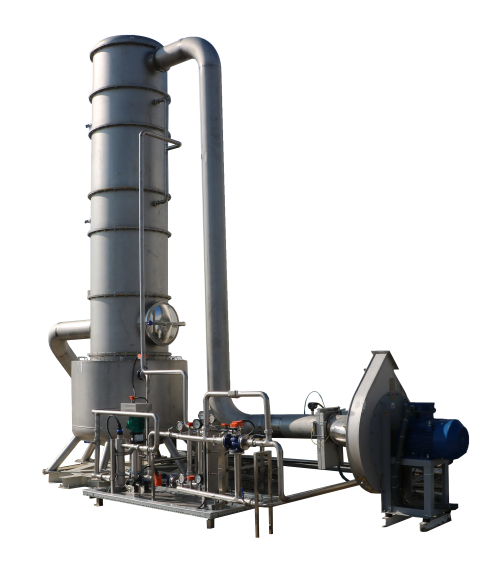

Our product portfolio includes high-efficiency cartridge dust collectors, baghouse filters, cyclone pre-separators, mist eliminators, and custom ventilation systems for both local and central extraction. All equipment is designed according to airflow demand, dust characteristics, filtration class, and ATEX (2014/34/EU) zoning requirements. For processes requiring enhanced explosion protection, our systems integrate NFPA-compliant design principles, including explosion venting, isolation, grounding, and safe-change (BIBO) technology.

Advanced filter media options such as nano-fiber cartridges, omniphobic coatings, flame-retardant surfaces, and conductive materials ensure low pressure drop and long filter life. With these options, APC systems maintain stable differential pressure even under demanding industrial conditions.

Effective air pollution control begins with proper source capture. Machine-mounted extraction points, hoods, and enclosures collect contaminants directly at their origin. Optimized duct velocities prevent dust settlement, while cyclones and material separators remove coarse particles before final filtration. Cleaned air can be safely returned indoors or exhausted outdoors, depending on regulatory needs and process requirements.

All APC systems are engineered under ISO 9001, ATEX, and NFPA guidelines. IIoT-based control panels continuously monitor differential pressure, airflow, filter status, energy consumption, and alarm conditions. Optional VSD-controlled fans and smart energy modes significantly reduce operating costs while ensuring stable air performance.

With decades of engineering expertise, APC provides tailored Air Pollution Control solutions that enhance operator safety, reduce downtime, and maintain full compliance with ATEX, NFPA, and pharmaceutical production standards across all demanding environments.